Product Lines

Hole Making

Hole Making Anti-vibration Tool Holders

Anti-vibration Tool Holders Milling

Milling Tooling Systems

Tooling Systems Solid Carbide Tools

Solid Carbide Tools Turning

Turning Accessories

Accessories

Hole cutting tool

- Rough Boring Tools

- Fine Boring Tools

- Boring System

- Cartridges for Boring System

- Drilling

- Automatic Telescope Back Boring Tool

- Inserts for Boring System

- Anti-vibration Turning Tool Holder

- Anti-vibration Boring Tools

- Anti-vibration Milling Tool Holder

- Special Anti-vibration Tool Holders

- API Ring Grooving Cutter

- Chamfer Milling Cutter

- Shoulder Milling Holder with Indexble insert

- Face Milling Cutter

- Side and Face Milling Cutter

- Modular Extensions for Tooling System

- DIN69871-A

- HSK-A

- HSK-T

- MAS403 BT

- PSC

- Solid Carbide Reamers

- Solid Carbide End Mills

- Solid Carbide Drills

- External Turning Tools

- Turning Inserts

- Center Block Tool Holder

- Boring Bar Series

- Sleeve

- Accessories

Modular knife (K interface)

- CBR Rough Boring Head

- NBR Rough Boring Head

- BR Rough Boring Head

- NLR Twin-flutes Rough Bor

- Rough Boring Tool with Al

- Rough Boring Tool for Ext

- Cartridge Rough Boring He

- Fixed Sized Boring Head

- CBF Fine Boring Head for

- CBF Micro-adjustable Fine

- NBF Fine Boring Head for

- NBF Fine Boring Head for

- NLF Rough Boring Head wit

- Fine Boring Head with Alu

- Fine Boring Head for Exte

- Cartridge for Fine Boring

- Boring Bar

- Shank Boring Bar with Typ

- Extensions

- Reducers

- Adaptor with Type PSC-K C

- BT MAS403 Adaptor

- DIN69871-A Adaptor

- HSK-A Adaptor

- Adaptor for Boring Tool w

- Morse Taper Adaptor for B

- Anti-vibration Tool Holde

- Heads for Anti-vibration

- Power Anti-vibration Tool

- Long Overhang Anti-vibrat

- Anti-vibration Tool Holde

- Anti-vibration Tool Holde

- Accessories

- Reduction with PSC Shank

- Extension with PSC Shank

- Extension for Shrink Fit

- Extension for ER Collet C

- Extension for Hydraulic C

- Extension for Tapping Chu

- Adjustable Adaptor

- Drill chuck adaptor

- Morse Taper with Draw Thr

- Morse Taper wtih Tang Ada

- Side Mill Adaptor

- Face Mill Adaptor

- Tapping Chuck Adaptor

- Shrink Fit Adaptor

- Weldon Adapptor

- Power Chuck Adaptor

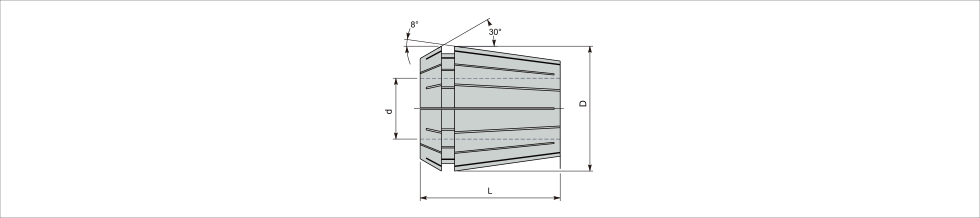

- High Precision ER Collet

- ER Collet Chuck Adaptor

- DIN 69893 HSK A Semi-fini

- Adjustable Chuck

- HSK-C Adaptor

- Micro Compensation Tappin

- Hydraulic Chuck Adaptor

- Face Mill Adaptor

- Power Chuck Adaptor

- Weldon Adaptor

- Shrink Fit Adaptor

- High Precision ER Collet

- ER Collet Chuck Adaptor

Product Lines

Product Lines Contact

Contact 简体中文

简体中文 English

English